File

download.File- Sheung Wan, Hong Kong

- +86 132 7001 9650

info@ws2002tm.com

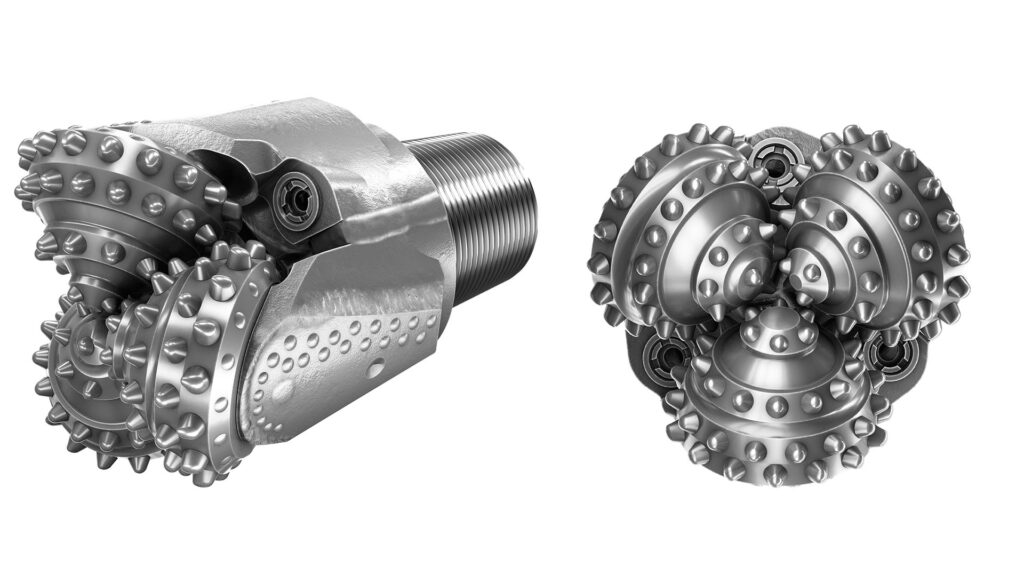

Carbide Tricone Bits

Carbide Tricone Bits

Tricone Bits Main features:- - High strength and wear resistance tungsten carbide, improve the strength and wear resistance of tooth. - A new journal bearing structure that significantly extends the working life of the bearing, which withstand moderate bit pressure and adapt to higher rotational speeds. - The new fluorinated rubber sealing ring improved performance, making it more suitable for the working environment and operating parameters of roller cone bits. - The new seal structure makes the sealing performance match the bearing, greatly increasing the service life of the drill bit. - The shirttail and head OD are protected by welding wear-resisting alloy and cemented carbide tooth. Product Description WS - Tungsten Carbide Insert bits have been developed for a wide range of drilling application from soft to the hardest strata. In this type of bit Inserts of special grade of sintered Tungsten Carbide are pressed into accurately machined holes in the alloy steel cone bodies, the exposed ends of the inserts form the cutting teeth of the drill bit. Different grades and shapes of Inserts are used according to the strata for which the bit is designed to increase the wear and fracture resistance of the cutting inserts and provide a faster rate of penetration of the drill bit. Three basic shape of Inserts are used:- Chisel Type - Chisel shaped inserts have opposing flats and a broad elongated crest, like the teeth of a steel tooth bit. These inserts are used for drilling soft to medium formation. Conical Type - Conical insert are cone shaped and have lesser protrusion they have good resistance to breakage and are generally used for drilling medium to hard formation. Spherical Type - Spherical insert have a very small protrusion and are hemispherical shaped ,they are used for drilling hardest formation. TCI Bits are of basically three types:- Soft Formation Bit - These are bit designed for drilling soft strata. Generally Chisel & Conical Type Inserts of greater height and less numbers are used to form the cutting structure. Maximum cone off-set(usually 5 degree) is maintained for such bit this results in maximum scraping - twisting action on hole bottom during drilling. Medium Formation Bit - These bits are designed for a wide field of application and are suitable for drilling medium to hard strata, most of the Inserts are Conical and Spherical for such bits. Moderate cone off-set (usually 3 degree) is maintained which results in chip and crush cutting and only slight twisting action during drilling. Hard Formation Bit - These bits are designed to drill the hardest and the most difficult to drill strata, the bit is designed to carry the maximum number of Spherical Inserts. Adequate protection is provided to the shirttail portion for bearing protection. The cone off-set is generally nil to give the cone a true rotation resulting in less gauging and scraping action and more of chipping and crushing action.

Gallery:

We offer best industrial services.

25+ years of experience

Manufacturing Technology Supports Factories around